UK5-HESILED24V brief introduction:

Lamp typeFuse terminalUK5-HESILED 24 is a product based on the improvement of UK5-HESI safety terminal. On the basis of its original product, a power-off indicator is installed to show the working state of fuse tube. Product current 0.5-6.3A safety pipe is available. There are black and gray colors. The color can be customized to meet the initial order. The product marking strip model is ZB8, without baffles and other accessories. Wiring capacity is 0.25-4 square millimeters.

UK5-HESILED24 Fuse terminal with lampProduct characteristics:

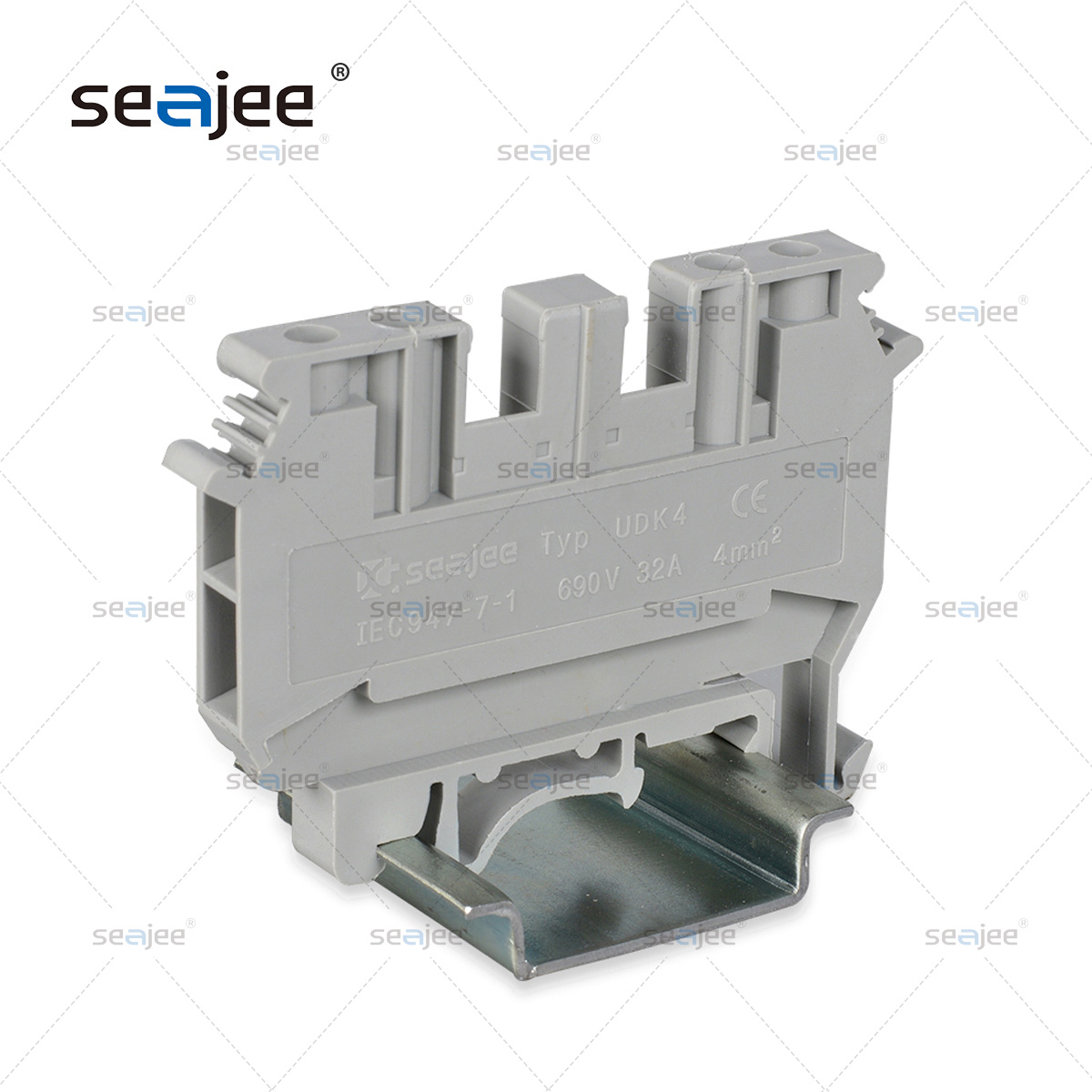

The terminal has a universal mounting foot, which can be easily and quickly mounted on U-type guide NS35 and G-type guide NS32.

The closed screw guide hole not only facilitates screwdriver operation, but also prevents the screw from loosening and falling out of the machine.

Potential distribution is accessibleConnection terminalThe central connector or or the edge connector inserted into the conical connection hole can be realized.

The terminals with multiple cross sections are equipped with general accessories, such as end plates, diaphragms, grouping diaphragms, etc.

The insulation shell is made of imported engineering plastics, spear amide (nylon) 66, which has high mechanical strength, good electrical performance and excellent elasticity.

The top two ends adopt white marking series, which can realize unified marking.

The breaking cantilever is used to connect the G-type fuse, and the operation is very convenient.

The enclosure is completely closed, safe and reliable.

The terminal with the luminous display will give the on-off signal of the fuse.

The current is determined by the fuse installed, and the voltage is determined by the selected luminous display.

Replacement method:

When the indicator lights up to indicate that the fuse has been fused, the fused fuse can be replaced directly or the whole terminal can be replaced directly. The method of safety pipe replacement is to open the cantilever of the terminal, remove the safety pipe stuck on the cantilever, and install a new safety pipe, then compact the cantilever. Replacing terminals requires inserting a screwdriver into the side of the terminal clamp foot and gently prying the terminal clamp foot. At this time, the terminal will be detached from the guide rail, and then the new terminal will be clipped into the guide rail to complete the replacement.